Epoxy Injection for

Concrete Crack Repair

Having to deal with the concrete crack repair is not something anyone of us wants to deal with, however, it is a fact of life. If you own a concrete slab anywhere, indoors or outdoors, you will at some point have a surface that cracks. Cracks, if left to grow, can become expensive inconveniences and hazardous areas for those walking on your surface! Reasons? Who knows… honestly, the reason for cracks can be a million things that either went wrong or have slowly gotten worse with weather or exposure. Epoxy injections were designed to create a way that is not only affordable but quick and easy to fix ugly cracks. This non-invasive process has many different benefits and specific installation techniques, continue reading to learn more.

Remove dirt and Debris

Don’t allow any extra water, dirt, or debris to be present within the crack you’re trying to repair because the epoxy injection will not take. Be sure to scout the area, know the daily weather, and have important equipment if you DIY.

Cons:

- The crack must be fully clean

- The crack must be dry

- The weather must be compatible with the epoxy you’re using

Pros:

- The epoxy injection will take for the life of the surface

- The injection will harden the area, so it doesn’t worsen

- The injection will not allow the crack to grow

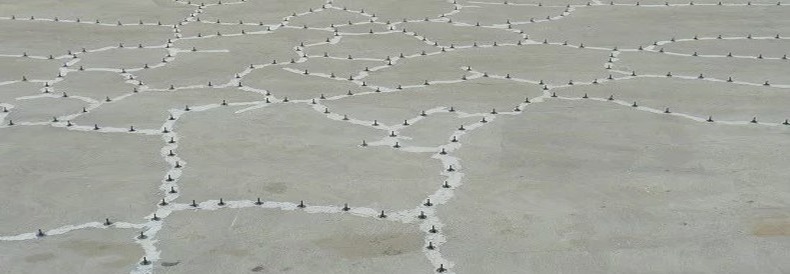

Setting the Epoxy Injections

It is important to be precise if you aren’t hiring a professional to perform the injections. All of the injections (if you’re using more than one) must be every 8 inches along the crack and then you need to coat the entire length of the crack with epoxy. Once the epoxy coating you using has hardened, the one securing the ports and crack, then it is time to get ready for the epoxy injections.

Cons:

- This is a time-consuming procedure if you are not functionally prepared

- The surface can be easily ruined if these steps are not taken properly

- Hiring a professional will be more effective

Pros:

- When done correctly, the epoxy is injected and hardens quickly

- Your concrete will look brand new

- The surface doesn’t have to be completely ripped out and replaced

Installation Process

Correctly executing the injection is important because it is the whole point! Start by injecting the epoxy from the lowest point to the highest point and work your way up. Be sure to read the instructions properly from whatever kit you purchase. Once the process is finished be sure that the area doesn’t have any spills, impact, or usage until it has dried.

Cons:

- Any moisture added or water spilled before the epoxy cracks will ruin the injection

- The surface will not be ready to be used immediately

- It is easier to have your surfaced repaired by a professional

Pros:

- This is a time-saving procedure, taking 30 minutes to an hour to be ready to use

- The area is incredibly strong and difficult to damage

- The cracks will disappear into the surface as if they were never there